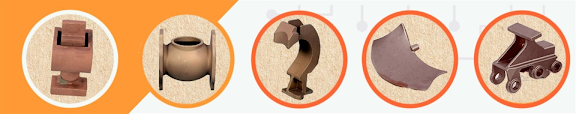

Make Complex Production Parts Easier with Investment Casting

Investment casting is the best process in many industries today for different purposes. It is the perfect option for a large scale and makes the ideal product. The casting process can handle with the help of various alloys. With copper investment casting, industries gain huge benefits for a complex application. In addition, you can access a reputable service provider in a field that is popular in the casting process. The casting process and production method are responsible for delivering quality components with good standards. Copper is the most popular item for investment casting due to heat exchangers, electrical connectors, nuts, bolts, and others.

Fulfill application needs:

Copper is

a well-known metal that manages good conductivity, flexibility, and resistance

to corrosion. On the other hand, metal may also alloy with other materials to

create a product for a vast array of applications. It is completely versatile

and easily combines with different alloys. You can take full advantage of such

metal casting like

·

Easy for post-casting process

·

Bearing qualities with lubrication

·

Less wear and tear

·

Good ductility

·

Corrosion resistant

·

Good electrical and thermal conductivity

It is a

suitable asset for different applications like electrical wire, ship

propellers, and plumbing fixtures.

Deliver

good performance:

Choosing

the right material is a major consideration for the industry today. Industry

prefers a material based on application and design. You can speak with

professionals to gather details about nickel silver investment casting and decide to utilize them.

·

It is effective for quality and fulfills the

tightest material standard.

·

Experts use an advanced technique to make the

casting with good precision.

·

Nickel-based material is highly durable and

manages great ability to bring good performance.

·

It manages robust chemical composition and

enables the material to withstand extreme and harsh hot operating conditions.

·

Nickel silver casting is better for resistance

to corrosion and makes them demand for the corrosive application.

Comments

Post a Comment